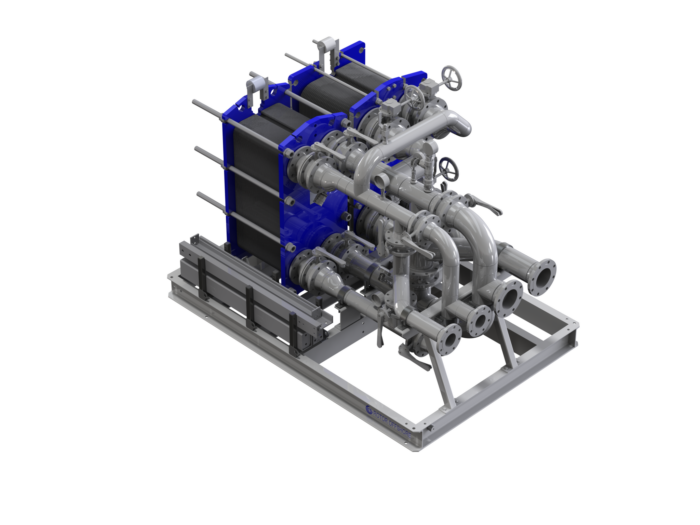

Cooling of mud while drilling with high mud return temperatures reduces temperature related operational problems with surface and downhole equipment and enhances operational efficiency. Built to match customer requirements, the Rotor mud cooler is the ideal choice to ensure continuous cooling of drilling fluid returns.

Units are designed to suit process requirements with regards to flows and temperatures as well as types of fluids and particle content (for instance lost circulation materials –LCM). Flexibility with regards to plate heat exchanger (PHE) configuration and operational sequences (series, parallel, single units) ensures suitability with operational parameters. Typical units are designed for 200-250 m3/h mud flow, cooling effect will depend on mud properties and cooling media temperature.