Engineering Services

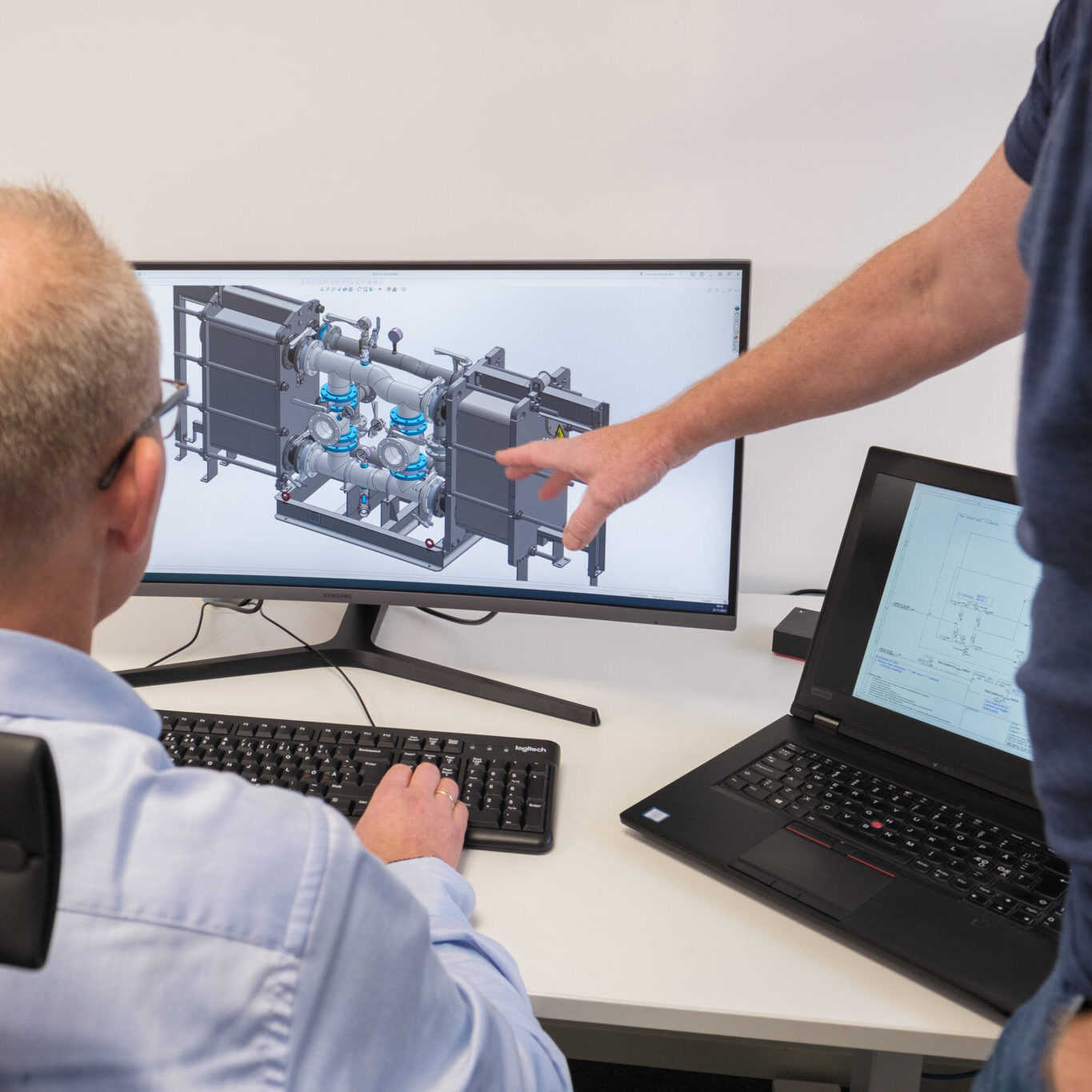

Rotor Systems provide experienced engineers in the design of low-pressure and high-pressure mud systems, offering engineering assistance across all project phases. From concept selection/design to project delivery, typical deliverables include PFDs, P&IDs, functional design specifications, etc. Rotor Systems specialists can actively participate or lead design reviews, Hazids, Hazops, and class meetings.